Drill Spindle

Overview

Drill Spindle  Drill Spindle with an Integrated drive motor |

The Drill Spindle (also called a drilling frame by many) is similar to a drill in the way it works. For use, it is held in a quick change tool post (QCTP), and the QCTP is bolted to a cross slide.

Collet

Drilling bits take various shapes, and some examples from Holtzapffel's Turning and Mechanical Manipulation, vol. 5 are shown to the left. New drilling bits, made with carbide cutting surfaces, are available from Chris Ploof at Ornamental Tools and a few other places.

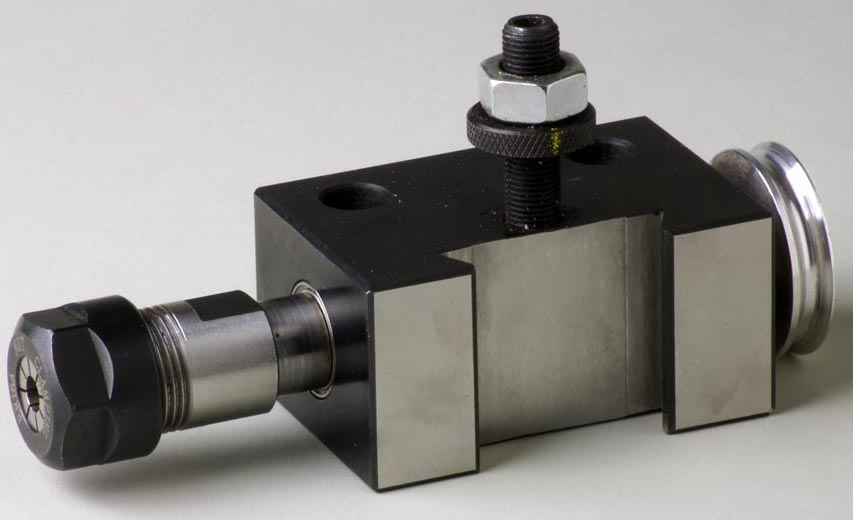

The newer style drilling bits are typically held in a collet (one is shown in the picture to the left), but Jacobs drill chucks have also been used. This collet is held in a collet holder. The drill spindle shown to the right has such a collet holder which spins freely in bearings in the tool.

It is also common to use milling bits in a drill spindle. When using such milling bits, 2-flute bits are recommended as they are better for evacuating chips when milling wood.

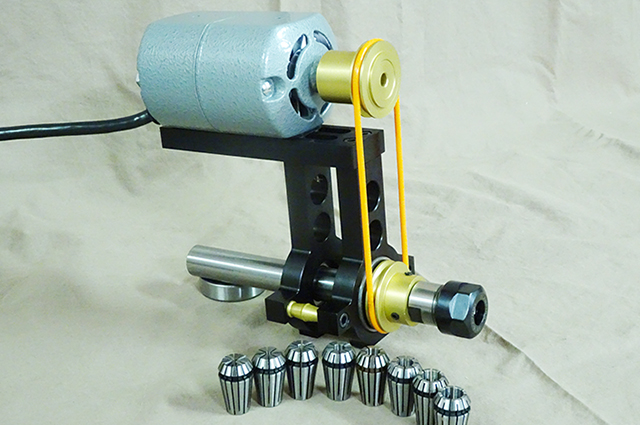

Whether a drilling bit or a milling bit is used, that bit (AKA, a cutter) is traditionally rotated in the drilling spindle using an overhead drive. Direct drive approaches can also used but they are more rare. (An example of a direct drive approach is shown above on the right.)

As with cutting frames, drill spindles can be purchased from a number of vendors, or you can make your own.

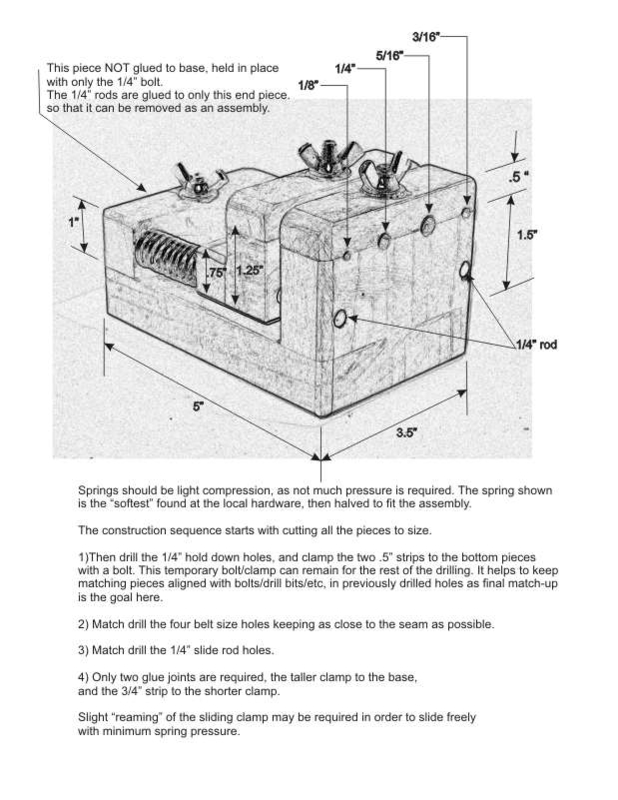

Notes on making one

Cutting Frames are not hard to make if you have a metal lathe (or access to one). A milling machine is also useful, but not required.

If you wish to make your own Drill Spindle, Bill Ooms has provided great directions. This design uses an ER style collet holder. This design works quite well, and an ER-16 can be used to hold up to a bit with a 3/8" shank.

Key Note: Drill Spindles are like cutting frames in that they are where the quality of ornamental cutting comes to life. If there is vibration in the drill spindle it will be transmitted to the cuts, and the quality of the work will be poor.

When you are using the ornamental lathe, listen for noise in the drill spindle. The drill spindle should have a whir like a finely tuned machine, and the noise level should be low. If there is vibration, the noise level will be higher. Sometimes much higher. And the tone of the noise will be higher:L It won't sound or run like a finely tuned machine.

Sources for buying one

Sources for buying cutters for one

- Ornamental Tools from Chris Ploof Designs

- Jon Spencer. You can contact him at jspencer.co@gmail.com.

Specifications and Replacement Parts for Commonly Available Drill Spindles

Jack Zimmel's Drill Spindle | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

Bearings |

6001-RZ - Sealed ball bearing: 12mm ID, 28mm OD, 8mm thick | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

More Information

Published Articles

- Precision Drill Frame Construction by Bill Ooms. Ornamental Turners International Newsletter, Volume 22, No. 2 - November, 2015, pg. 18

- Spencer Drills and Cutters by (unknown).

- Ornamental Turners International Newsletter, Volume 24, No. 1 - Spring, 2017, pg. 25

- Rose Engine News, Volume 7, No. 1, Spring-Summer, 2017, pg, 12.

Books and Papers

- Eccentric Turning, by an Amateur (actually, Nathaniel Brown Engleheart)

Web Sites

- Bill Ooms’ Resources -- Ornamental Turning Chucks & Cutting Frames. This web page has many resources for making your own drill spindle.

|

Disclaimer: eMail comments to me at OTBookOfKnowledge @ Gmail.com. The process of woodturning involves the use of tools, machinery and materials which could cause injury or be a health hazard unless proper precautions are taken, including the wearing of appropriate protective equipment. |