Sharpening

Overview

Jon Magill wrote a really great article where he wrote:

Historical Approach

With regards to sharpening, the method outlined by J.H. Evans in Ornamental Turning in 1903 is

- Primary Bevel

- Use an oil stone

- Use a brass plate with oilstone powder and oil

- Secondary / Micro bevel (Evans recommended +3°)

- Use a brass plate with oilstone powder and oil

- Use a cast iron plate with very fine crocus powder and oil

- Debur - very lightly on the back side

- Use a cast iron plate with very fine crocus powder and oil

Sharpening Media

Oilstone Powder is very hard to find these days. One can find it occasionally on eBay or other similar sites, but similar products are available from clockmaker suppliers. One which offers such powders is Ernst Westphal.

Diamond-based lapping compounds should be a very effective alternative.

I have not done any testing with ornamental tools, but products like Kent Grit Diamond Lapping Paste Polishing Compounds should be usable. They are oil based and come in grits from 40 microns, all the way down to 0.25 microns. When used with paper wheels on a grinder, they are very effective for polishing knife edges to be better than razor sharp.

Current Approaches

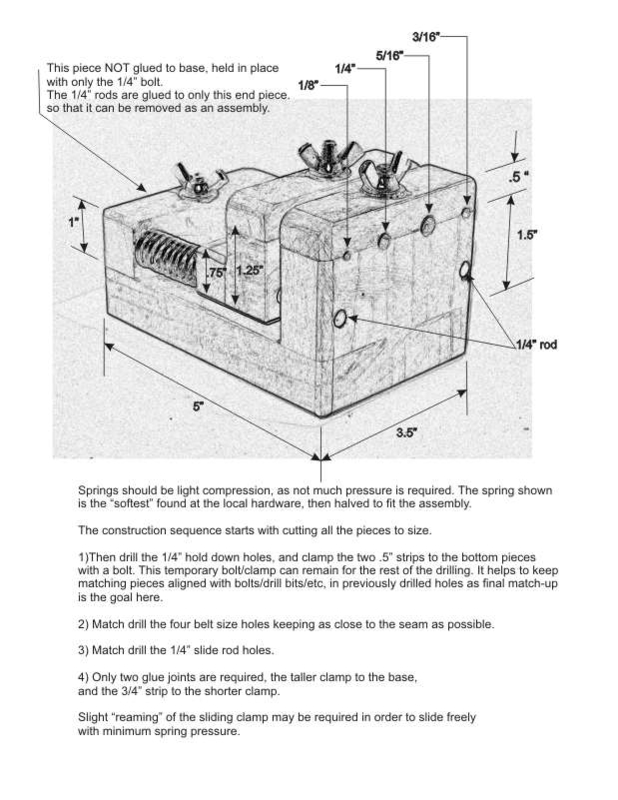

When sharpening by hand, a Goniostat is often used.

The Accu-Finish machine has been used for years by machinists, and is also used by some ornamental turners. These machines use diamond wheels, or a ceramic lapping wheel with a diamond spray. This is a really great machine, especially as it has a built-in goniostat. But it can be a bit expensive.

I've found the Tormek grinder to meet my needs, though I did have to make some of my own jigs.

More Information

Published Articles

- Build an Overhead Drive, by Jon Magill. American Association of Woodturners' "American Woodturner", Volume 23, #1 - Spring 2008, pg 30

- Fixed Tool Technique on a Rose Engine by Al Collins. Al gets into how he sharpens his fixed tools in this article. Ornamental Turners International Newsletter, Volume 27, No. 2 - October, 2020, pg. 4

- Preparation of Cutters for LE Cutting Frame by John Tarpley. LW Rose Engine News, Volume 1, No. 1</a> - Spring-Summer, 2010, pg. 7

Books and Papers

- Industrial Recipes, A Collection of Useful, Reliable, Practical Recipes, Rules, Processes, Methods, Wrinkles, and Practical Hints Forming a Reliable Workshop Companion for All Engaged in the Various Industrial Arts and Trades, (1913) by Dr. John Phin, pg. 116-117

- Ornamental Turning, (1903) by J.H. Evans, Chapter VI

- Turning and Mechanical Manipulation, Vol. 3 - Abrasive and Miscellaneous Processes, Which Cannot be Accomplished with Cutting Tools (1850), Charles Holtzapffel, chapter XXXII .

Web Sites

- The Sharpening Handbook is intended to also be a good resource for data about sharpening fly cutters. There is information on both round rod cutters, and traditional cutters. This site is especially useful if you are looking to use a Tormek grinder.

- Ed French created a number of sharpening jigs, and has posted them on GitHub in his folder, SharpeningJigs. Ed posted the STL files, along with the Fusion 360 F3D files. Both the goniostats and the the pucks have a PDF in the folder discussing their use. Ed noted,

These pucks are designed to be used manually on a flat diamond hone or knife sharpener as well as on lapping machines. The carbide cutters are called split end or half straight. The pucks and goniostats can be 3d printed with 30% infill. The 3dPrintModifier may be used in slicer software to increase infill to 100% around the holes in the pucks.

Presentations

- This YouTube video shows a demonstration of an Accu-Finish that was given at the 2018 OTI Symposium.

- Ed French gave a demonstration to the club about his 3D-printed sharpening jigs. The recording for this video is in the Ornamental Turners Int'l (OTI) member meeting videos, December 2022.

|

Disclaimer: eMail comments to me at OTBookOfKnowledge @ Gmail.com. The process of woodturning involves the use of tools, machinery and materials which could cause injury or be a health hazard unless proper precautions are taken, including the wearing of appropriate protective equipment. |