Ornamental Turning Without a Rose Engine Lathe

Overview

|

These items are reviewed below: |

These items have articles elsewhere in the Ornamental Turning Book of Knowledge: |

Beall Pen Wizard

This machine can be used to make some really nice ornamentation on objects like pens, duck calls, wine bottle stoppers, etc. It is a very nice design and works quite well.

There are some features which make this a very useful option:

- The cutter has a guide which rides along the surface, allowing it to follow any surface shape,

- Both ends of the object are supported, so the method of work holding is less critical, and

- The cost for entry to use this approach is quite low.

The newer model has swapped the ends so that you can more easily see what you are turning. There is also an adapter for holding the object via a collet.

This machine combines an Indexing Wheel, with a Reciprocrator, and a Curvilinear Apparatus.

- This YouTube video, The Pen Wizard and Ornamental Mill, shows it in action.

Alas, Mr. Beall has retired and closed up shop. I understand that Lee Valley has taken over his product lines, so the Pen Wizard may be available from Lee Valley.

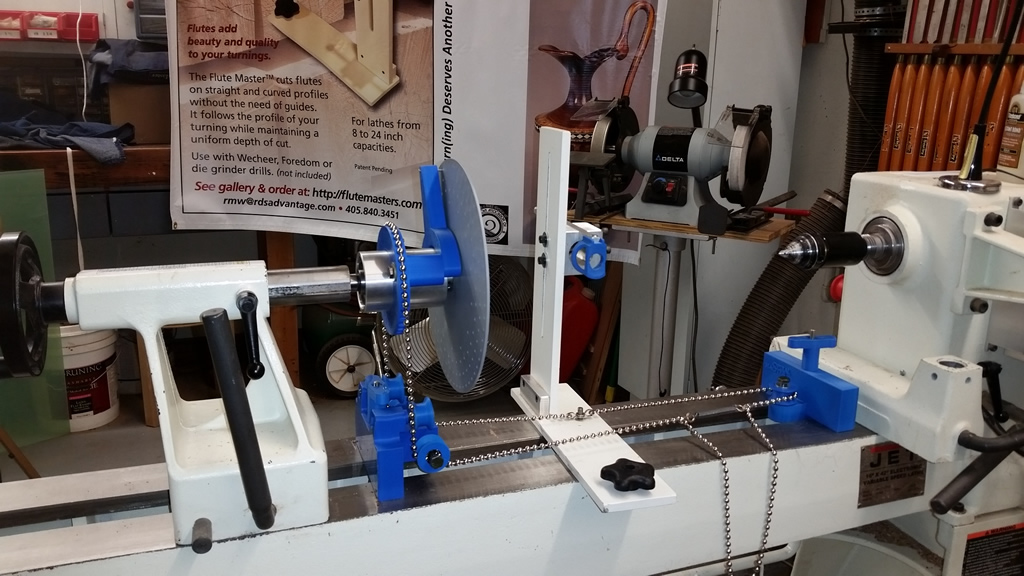

Flute Master's Spiral Master

his jig enables the cutting of spirals on an object using the traditional lathe on which the object was originally turned. It comes after the success of the Flute Master, and they have even added a Variable Pitch Tool for spirals.

I've not used these jigs, but the brisk sales indicate they are successful for certain applications. One area where they probably excel is for larger vases/urns and columns.

As above, there are some features which make this a very useful option:

- The cutter has a guide which rides along the surface, allowing it to follow any surface shape,

- Both ends of the object are supported, so the method of work holding is less critical, and

- The cost for entry to use this approach is relatively low, especially if one is making repetitive work.

This jig combines an Indexing Wheel, with a Spiral Apparatus, and a Curvilinear Slide.

- This YouTube video, Spiral Master II, shows it in action.

JaHo Ornamental Turning Device

The JaHo Ornamental Turning Device is the brainchild of the Dutch turner Jan Hovens, and is sold by Dreschselbedarf, a German company. There is a good write-up about it on Bowl Maker.

I've not used this device.

- This YouTube video, JaHo: ornamental turning device for woodturners, shows how to use the JaHo Ornamental Turning Device.

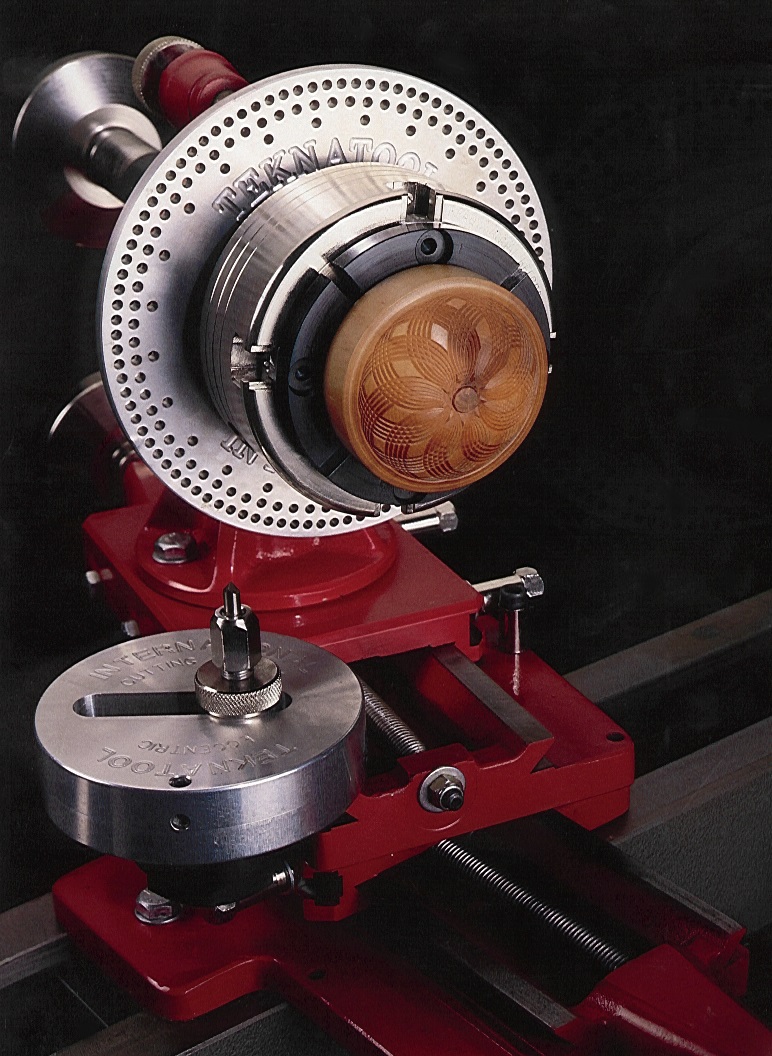

NOVA Ornamental Turner

Teknatool sold this device for a while, but have discontinued it. It is still available periodically as a used tool -- one sold for $650 on the AAW member forum in 2020.

I've not used this device.

- This YouTube video, NOVA OT unit -- End cutting action, shows it in action, cutting on the end of an object.

- This YouTube video, NOVA OT unit -- Side cutting action, shows it in action, cutting on the side of an object.

Sorby RS3000 Ornamental Turning Device

The Sorby RS3000 Ornamental Turning Device was designed by Martin Thompson-Oram and marketed by Sorby in the mid 1990's for just a couple of years.

The following was posted on WoodWorkForums.com in 2012:

It has been a bit of a unicorn, and I could not find much information about it. The sum of it is below.

- AAW's December 1997 edition of the American Woodturner

- United States Patent No. 5,435,215, dated 25 July 1995

I've not used this device, so I cannot speak to how good it is. In talking with Jeff, he said it was remarkably good, but added that he was probably going to sell it.

Update: In April 2022, Jeff Hankinson sent me some pictures of his, and also posted the video below on YouTube. He added these comments:

This YouTube video, Sorby RS 3000 Demo, shows it in action.

|

Disclaimer: eMail comments to me at OTBookOfKnowledge @ Gmail.com. The process of woodturning involves the use of tools, machinery and materials which could cause injury or be a health hazard unless proper precautions are taken, including the wearing of appropriate protective equipment. |